Servo Motor Repair

24-Hour Emergency Service

If you own a servo motor, you are probably aware of its high-tech precision and the ability to position its output shaft at an angle, position and velocity that is not possible with other motors. High precision and close tolerances are critical.

The ability to offer Servo motor repair requires technicians that understand Servo motors and can expertly repair them to manufacturer specifications. Spina Enterprises is a company that passes this critical test, just like we do for all of our motor repair jobs.

Servo Motor Types & Applications

Here are some specific Servo motors types and their applications that can be serviced or repaired at Spina Enterprises:

- DC Servo Motors – computerized numerically controlled machines

- AC Servo Motors – automation, robotics, CNC machinery, and other applications a high level of precision and needful versatility.

- Positional Rotation Servo Motors – radio-controlled water, radio-controlled cars, aircraft, robots, toys and many other applications

- Continuous Rotation Servo Motors – radar dish on a robot or as a drive motor on a mobile robot

- Linear Servo Motors – actuators in higher model hobby airplanes

Servo motors are also used in many other applications. They include robotic machines, bottle labeling and packaging, cameras, robotic vehicles, solar tracking systems, metal forming and cutting machines, textile machines for spinning, weaving or knitting, automatic door openers, and more. Regardless of your application, contact us for all your Servo motor repair needs. We’ll do all we can to help get your motor working like new.

Servo Motor Diagnostics, Servicing & Repairs

Servo motors break or function poorly for a variety of reasons. Here are some of the diagnostic tests, servicing, and repairs that Spina Enterprises performs.

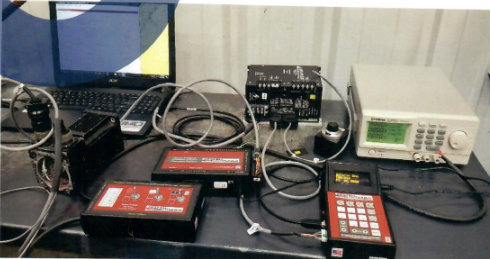

Diagnostics

- Visual Inspection – checks parts including terminals, connectors, shaft, keyway, and endbells

- Surge Comparison Test – determines if the stator needs rewinding

- Insulation Resistance (or megger) Test – determines adequate insulation

- KE test – verifies the condition of magnets in the motor

- Feedback – ensures feedback is functioning properly

Servicing and Repairs

Servicing a Servo motor is a process that is similar for all units. Here are the steps we use at Spina Enterprises:

- Disassemble the unit – To disassemble a Servo motor, the backplate is removed. Next, the encoder and its housing are removed, including disconnecting the wiring. The endbells are then removed so the rotor can be pulled from the stator and both rotor and shaft can be inspected. Finally, the bearings, bearing housing, and brake apparatus are removed.

- Clean the unit – Spina Enterprises uses an alkaline washer to clean Servo motors. This method is superior to hand cleaning or pressure washing.

- Change the bearings – Bearings are the #1 cause of failure in Servo motors. As a result, we replace all bearings every time a motor is serviced.

- Implement other repairs – Depending on the diagnostics and testing, additional parts may need to be replaced.

- Testing – After the unit is reassembled, several tests are performed to ensure it is functioning properly. Types of testing at this stage include the feedback test and a memory test to ensure alignment of the feedback device.

- Packaging – If needed, we’ll repaint your Servo motor before returning it to you.

Brands

The brands we service include those listed below . . . and many more! If your brand is not listed please contact us to see if we can help.

- Allen-Bradley

- B + R

- Baumuller

- Berger Lahr

- Bosch

- Danaher

- Elau

- Fanuc

- Heiderhain

- Indramat

- Kawasaki

- Kollmorgen

- Mitsubishi

- Omron

- Nacl

- Parker

- Renco

- Sanyo Denki

- Sick Stegmann

- Siemens

- Sumtak

- Tamagawa

- Toshiba

- Yaskawa

At Spina Enterprises, not only will your Servo motor be repaired right, but throughout the process, you’ll appreciate our knowledgeable technicians, friendly staff, and excellent service. Contact us to repair or service your Servo industrial motor. We’ll have you up and running in record time.